Product Specification

-

Product Name : Window Clamper

-

Material : SKD 11

-

Machines : Van, Okamoto, Sibu

-

Accuracy : ±0.05mm

-

Usage : Semi-conductor precision part

Product Description

From SKD 11 to finished product, connector die, it has gone through 3 processes: milling, grinding and wire cut.

At In Future Precision, we have many imported machines like Makino IQ300, Amada GLS5T Optical Profile Grinder, Wenzel CMM, Sodick Linear Die Sinker and etc to ensure the high precision and accuracy of our products. With ISO 9001 : 2015 certificate. We are capable of manufacturing precision parts for automotive, electronic, medical and semi-con industries.

Our Advantages

Optimizing Materials - Ensure Product Quality

We guarantee the product quality from the source. By cooperating with domestic and foreign suppliers to select the steels and metals, we are able to ensure the product quality and the life span.

Imported Machines For High - Precision Needs

We have our own production plant and with a number of milling machines, grinding machines and and other equipment that are imported from Japan, We can meet your high-precision needs.

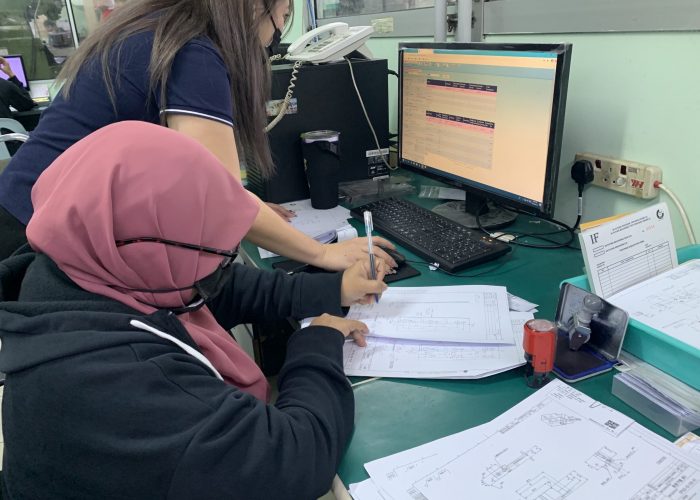

Deep Interpretation Of Drawings

Our boss with more than 30 years of experience in precision parts and tooling leads the technical team to interpret the drawings and manufacture. With many years of experience, we can quickly manufacture the qualified sample.

Opening Hours :

Monday : 8:30am – 6:15 pm

Tuesday : 8:30am – 6:15 pm

Wednesday : 8:30am – 6:15 pm

Thursday : 8:30am – 6:15 pm

Friday : 8:30am – 6:15 pm

Saturday : Closed

Sunday : Closed

IN FUTURE PRECISION SDN. BHD.

Address : 37, Jalan Rajawali 3, Bandar Puchong Jaya, 47100 Puchong, Selangor, Malaysia

Contact us :

H/P : +6014 63 43932 (Mr.Mok)

Tel : +603 8070 7391/2/3

Email : [email protected]